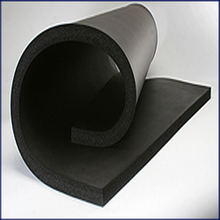

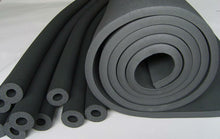

RUBBER INSULATION

Closed Cell Tubing & Sheet Insulation is a flexible and lightweight elastomeric thermal insulation designed for insulating liquid cooling and heating lines, ductworks, tanks and vessel. The expanded closed cell structures forms a vapor barrier to prevent sweating or condensation on cold lines and frost formation on cooling systems, chilled water and refrigeration lines. It also efficiently retards heat loss on hot lines. Stable thermal conductivity during service, due to its dense surface skins and closed cell characteristic. It provides quick and efficient way to insulate pipe. This insulation is used for such systems as plumbing, hot water heating, airconditioning and refrigeration. It is highly flexible, elastomeric materials. It is quick and easy to install on piping or tubing. It protects pipes against corrosion and acts as a vibration damper. The talcum powder on the thick and inner skin help to speed up pre-assembly lines or by using existing lines using adhesive.

👍 Low thermal conductivity (K-Value) which makes it highly efficient and effective in the insulation of cooling or heating systems

👍 It is suitable for application within the temperature range of 25 degree C-+105 degree C.

👍 Rubber Insulator has excellent ozone and ultraviolet resistance.

👍 It is CFC, asbestos, chlorine and fiber free and does not cause skin allergy.

👍 It is also inert to most chemical agents and neutral to pipe metals.

👍 It is able to withstand tearing, rough handling and sever site conditions.

👍 At -25 degree C, this Closed cell Insulation becomes hard and as temperature drops below -25 degree C it becomes increasingly brittle; however, this hardening characteristic does not affect the thermal efficiency or water vapour permeability. On heating cycle, Rubber Insulation will withstand temperature up to 105 degree C.

👍 The smooth surface material gives the finished installation a neat and aesthetic appearance. No coating is necessary in most indoor installation.

👍 The average physical properties and values obtained in accordance with the accepted method.

Installation Recommendation

Piping and Tubing Installation:

Pipe Insulators, provide a quick and efficient way to insulate pipes for refrigerator, cooling and heating. Insulation material should be lifted on pies that are dry, clean and unheated.

There are two major methods of affixing pipe and tubing insulation materials unto your desired fitting. The slip-on method, which is used mostly for new pipes before they are connected or installed. The other method, the snap on methods is for pipes that have already been installed or connected.

Tubing can be easily cut and fashioned into fittings for either joints like bends, Ts and elbows. For screwed fittings, sleeve fitting covers should be made from tubing of the same thickness as the used pipe. The inner diameter must be large enough to overlap the first insulation material on the pipe.

It is important not to compress the tubing material as the insulation values may be compromised and condensation may occur. Select the right size tubing insulation for the pipe to be insulated. Avoid stretching the material over the pipe. The length of the insulation tubing should cover the section of the pipe adequately, this is to ensure that there will be no strain on the surface joints of the tubing and the pipe. Seal the seams and joints accordingly.

For your inquiry and other concern and for fast transaction, you may call us at our hotline # 0963 1631840.

Happy Shopping....!!! 😊

We have wide range of Insulation and Construction materials…We can definitely help you serve your needs…

RITEMORE ENTERPRISE

Office Address: 18 Horizon St., SSS Village, Concepcion 2, Marikina City

Telefax: (632) 72163280 / 89974032 Viber: 09631631840 / 09175530994

Website: www.ritemore.com

Facebook page: facebook.com/ritemore

Email Ad: sales@ritemore.com